KEIL Undercut Fixing System

KEIL Befestigungstechnik GmbH

KEIL is a leading manufacturer of facade systems with undercut technology. With the aid of high-class facade panels, dreary building shells can be transformed into fascinating design objects. For architects, they provide countless possibilities for creativity. The secret behind this is the invisible attachment with an elaborate fastening, called undercut technique.

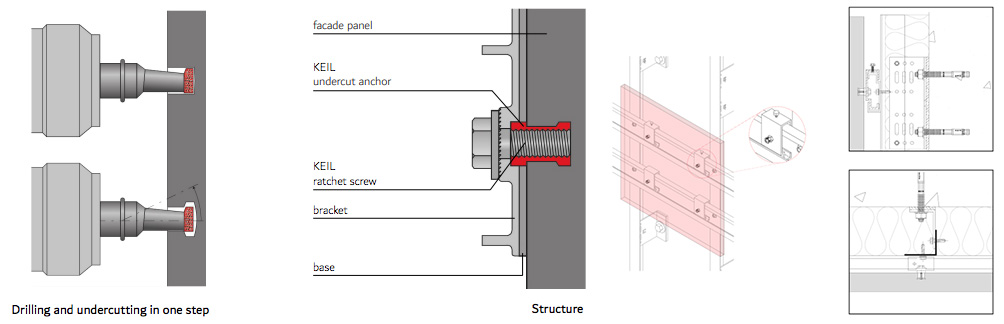

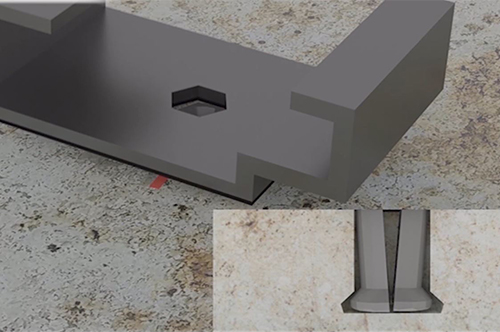

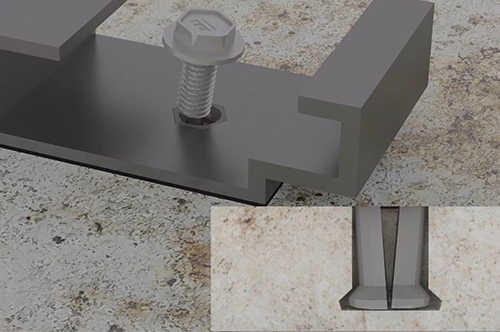

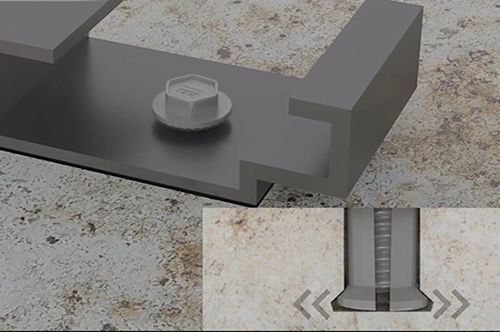

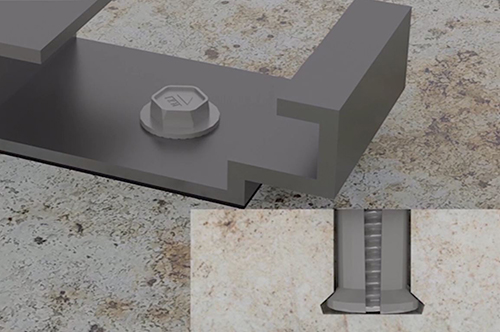

This technique is as simple as it is ingenious. By means of a patented drilling system, a blind hole with an expanded base is drilled into the backside of the facade panel. Subsequently, the KEIL undercut facade anchor is inserted into the hole. This anchor guarantees a positive-locking fixing, which is free of expansion force. As soon as the panel is equipped with the facade anchors, it can be easily mounted onto the ventilated supporting construction. The hidden undercut façade anchor keeps the aesthetics of the facade panel free from visible drill holes and other distracting elements.

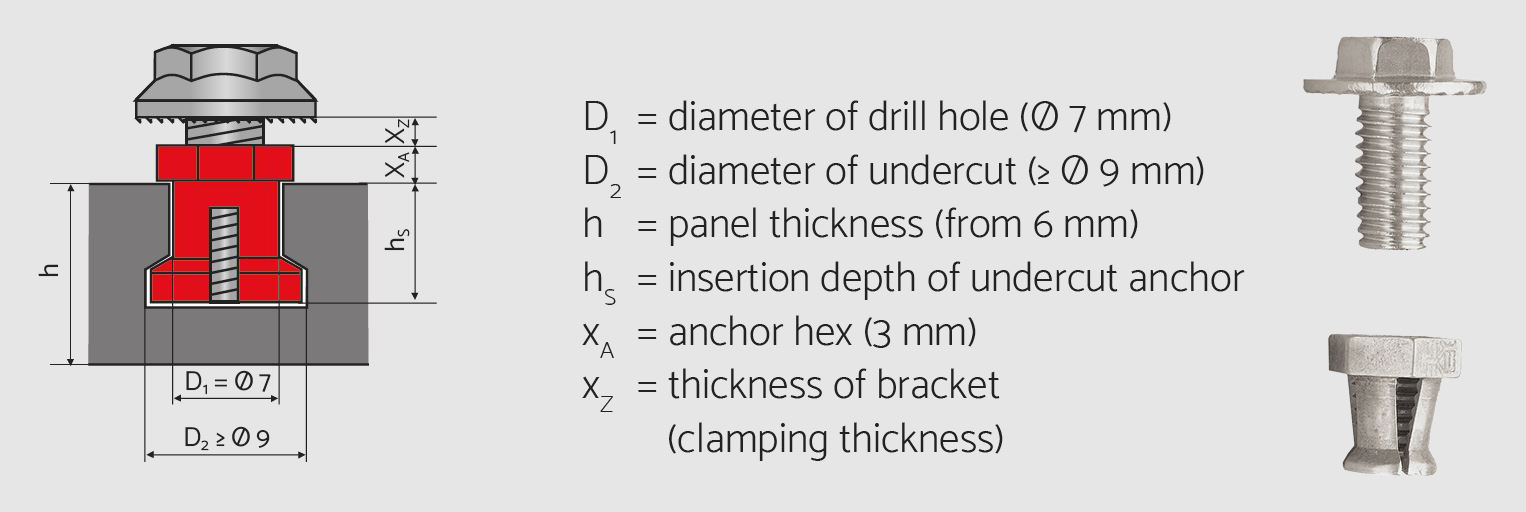

KEIL Undercut Anchor

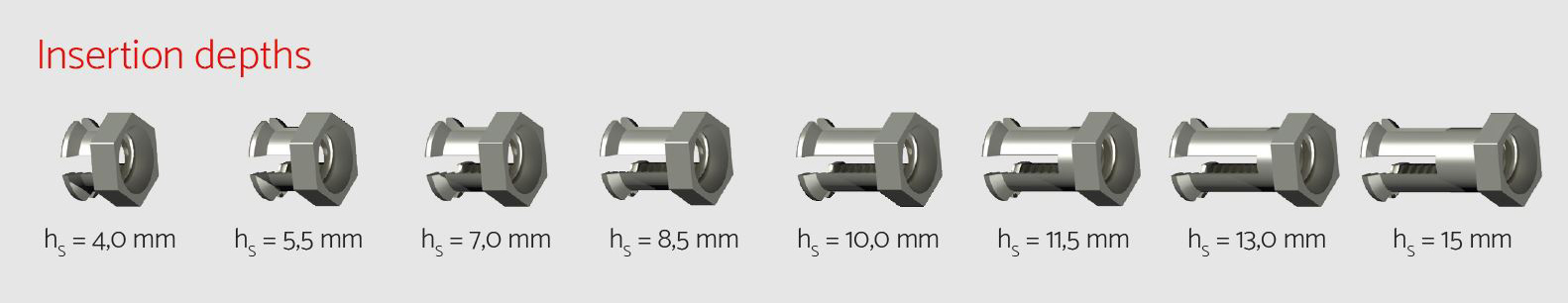

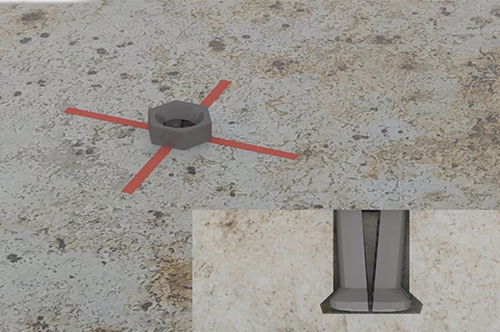

The KEIL undercut anchor for the hidden attachment of thin panels is manufactured from stainless steel. Its geometry, which matches the KEIL undercut drill hole, guarantees an attachment free from expansion pressure in all common panel materials from a panel thickness of 6mm onwards. Different insertion depths are possible, depending on the thickness of the panel or the necessary bearing capacity. The KEIL undercut anchor is designed to carry more weight than that of the panel material. Due to its high assembly safety, the KEIL undercut anchor offers significant advantages.

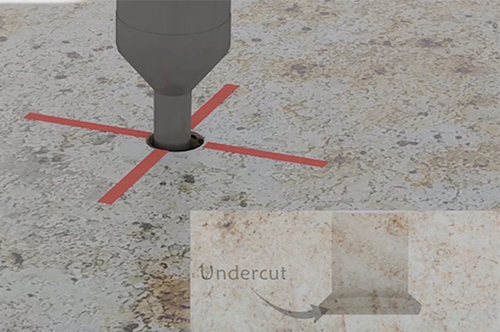

Drilling

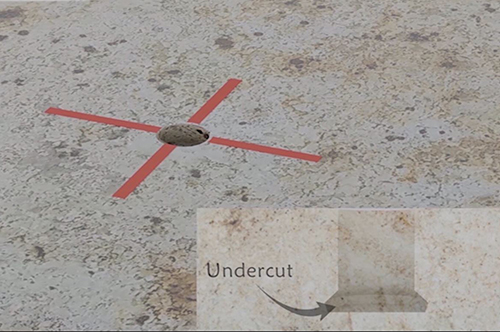

Undercutting

Assembly

The Process

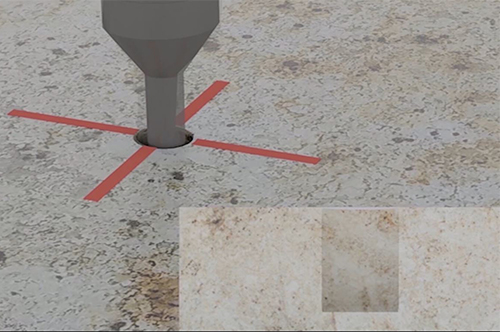

- Cylindrical drilling and conical undercutting are carried out in one single process and by only one tool

- Different levels of automation are possible, depending on the type of machinery and the material of the panel

- Drilling time for ceramics is less than 10 seconds

- Panels of any desired size and weight will get a patented undercut in a precise and consistent symmetric shape

- For the assembly, an undercut anchor is inserted into the hole and locked positively by a screw

- The assembly is fast, safe and simple