GIP GmbH

Tailor-made Facade Systems

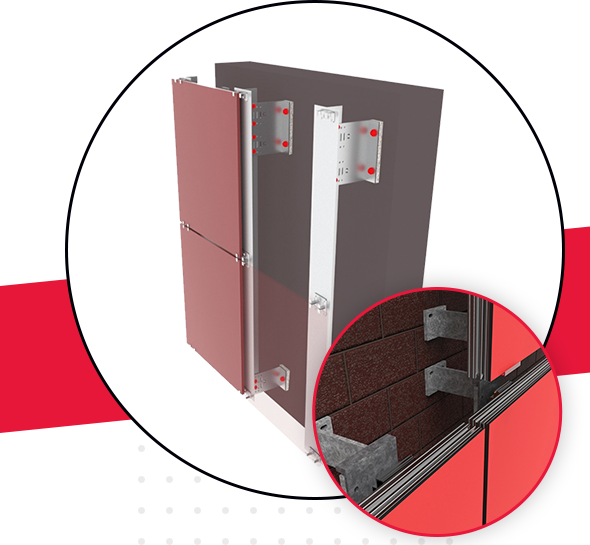

GIP GmbH is a manufacturer of metal substructure systems for ventilated curtain walls. Our VECO® aluminium and steel substructure systems offer standardised solutions for fastening all widely used facade cladding materials. Each standard system is then supplemented by custom-made components specific to the project.

KEIL Befestigungstechnik GmbH

Undercut Fixing System

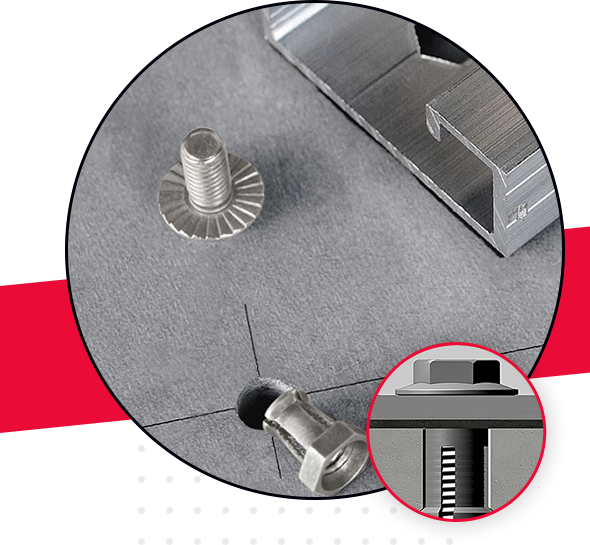

KEIL is a leading manufacturer of facade systems with undercut technology. With the aid of high-class facade panels, dreary building shells can be transformed into fascinating design objects. For architects, they provide countless possibilities for creativity. The secret behind this is the invisible attachment with an elaborate fastening, called undercut technique.

This technique is as simple as it is ingenious. By means of a patented drilling system, a blind hole with an expanded base is drilled into the backside of the facade panel. Subsequently, the KEIL undercut facade anchor is inserted into the hole. This anchor guarantees a positive-locking fixing, which is free of expansion force. As soon as the panel is equipped with the facade anchors, it can be easily mounted onto the ventilated supporting construction. The hidden undercut façade anchor keeps the aesthetics of the facade panel free from visible drill holes and other distracting elements.

Metawell® GmbH

Aluminium Lightweight Panels

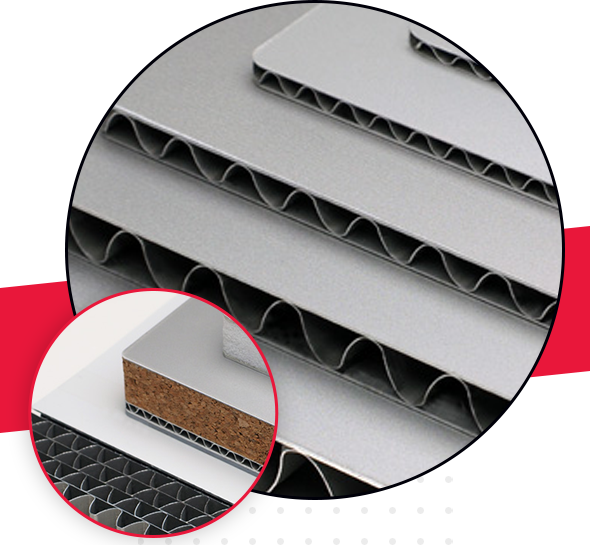

At the company’s location in Neuburg in Germany, the company Metawell® GmbH has been producing and developing aluminium sandwich panels and lightweight components successfully for over 35 years.

The very light but extremely rigid sandwich panels are used for numerous applications. In addition to lightweight panels, the company also provides extensively pre-fabricated components, customized lightweight solutions and special products.

Metawell® is a patented lightweight sandwich panel consisting of two aluminium sheets with a corrugated aluminium core. The layers are glued together in a continuous manufacturing process. The aluminium is primered with a special coating, which guarantees a durable adhesive compound and a good corrosion protection. The lightweight and rigid panels enable high weight savings, especially in large formats.

ISO-Chemie GmbH

Modern Sealing Technology

The technical requirements of energy-efficient and long-term building seals are increasing all the time. ISO-CHEMIE’s innovative products solutions have a positive effect on the energy balance of buildings, at the same time promoting a healthy internal climate. Factors such as airtightness, permanent movement, weather resistance, emission free, thermal and acoustic insulation as well as humidity and fire protection are important properties of a standard conforming building seal. The constant quality of our sealing system is monitored regularly by independent institutes according to the very latest standards and regulations.

As a leader in sealing technology, ISO-CHEMIE has a range of high-performance joint sealing products for window installation, in front of the wall installation, solid construction, industrial/commercial construction and metal facade construction. Their sealing solutions help to achieve a positive building energy balance. The system components specially developed for reliable building waterproofing are coordinated in function and application and meet the strict requirements of the Building Energy Act.

They supply high quality pre-compressed joint sealing tapes, which are especially designed and manufactured to provide the best sealing solution for the following applications:

-

- Construction joints (including moving joints)

- Precast Concrete joints

- Skylights

- Between cladding panels

- Curtain Walling

- Perimeter seals around windows and doors